Gasketed Plate Heat Exchangers

Achieving the balance between energy efficiency, optimal performance, and dependability is a complicated equation that is easily solved with Thermalines full line of Gasketed Plate Heat Exchangers.

Learn More

Corrugated Tube Heat Exchangers

Thermaline Corrugated Tubular Heat Exchangers utilize turbulence-inducing corrugations that increase heat transfer efficiency and promote even thermal disbursement without compromising product integrity.

Learn More

Shell & Tube Heat Exchangers

Repeated dependability, time after time! Thermaline’s full range of Shell & Tube Heat Exchangers have proven to be reliable in the most demanding process environments by the most demanding processors.

Learn More

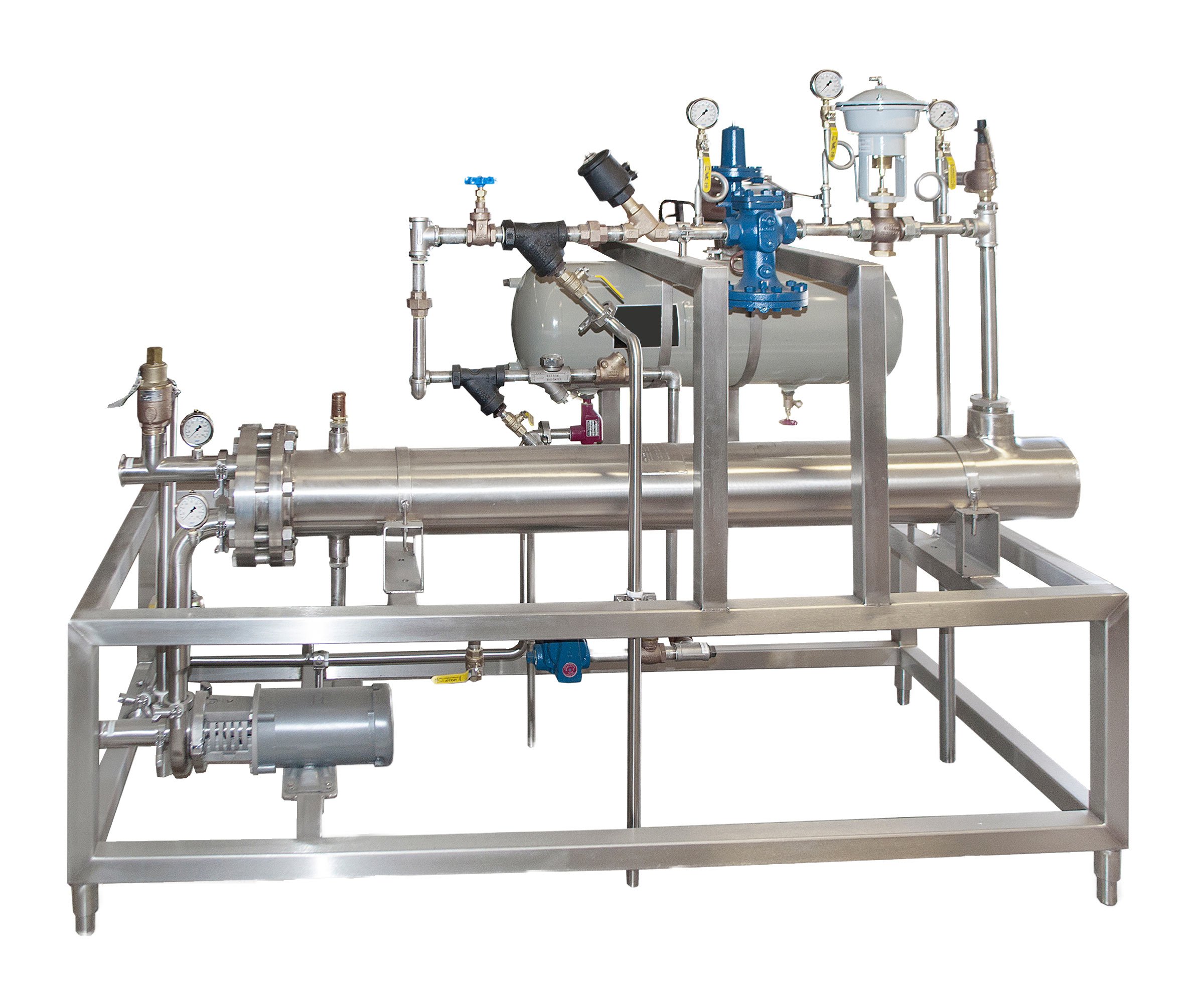

Hot Water Sets

Self-contained turnkey Hot Water Sets for all of your process and utility needs. Close approach temperatures, precision control, and dependability all come standard on every Thermaline Hot Water Set.

Learn More

.

Photos

Videos

Documents